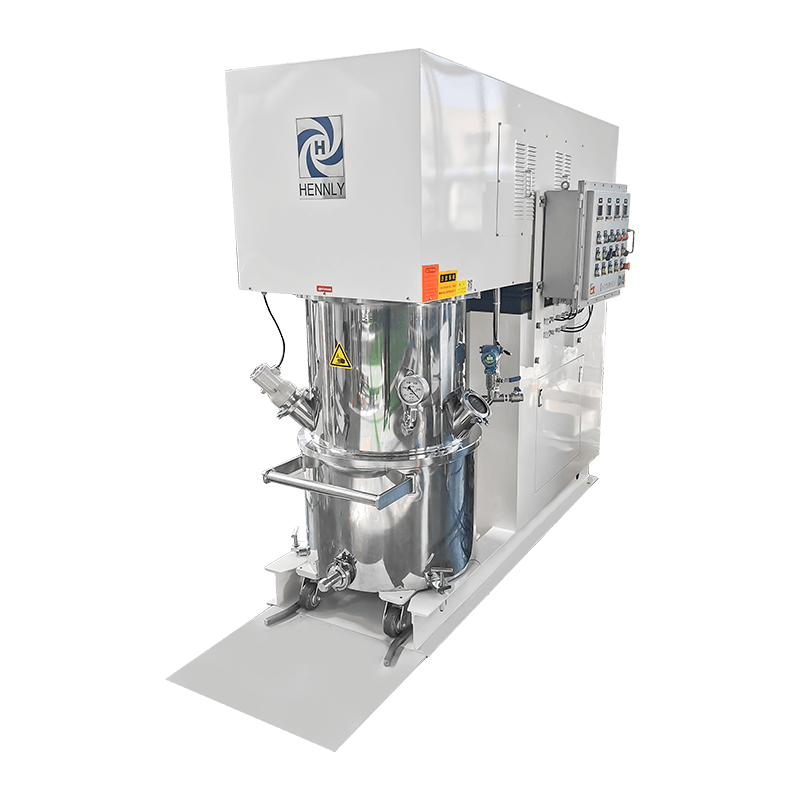

Triple Planetary Mixer

About HENNLY

NanTong Hennly Machinery Equipment Co., Ltd. is China Triple Planetary Mixer Suppliers and Wholesale Triple Planetary Mixer Manufacturers that combines industry and trade, focusing on the research, development, and production of hybrid equipment. We have advanced processing equipment and a team that has served the mixer equipment industry for many years. Our employees have expertise, extensive application experience, and the ability to provide customers with a full range of process services from equipment selection to production. Based on high-quality and high-end markets, we mainly export to countries such as the United States, Germany, Japan, South Korea, Malaysia, Singapore, Vietnam, Indonesia, and Egypt. The areas of cooperation with clients include pharmaceuticals, adhesives, thermal conductivity and heat dissipation, slurry, solder paste, batteries, polymer materials, food, and chemical industries.

- Wide range of applications

- 15 years of precipitation of technical design

- Non-standard customization (it can be customized according to customer needs)

- Direct docking service of factory

-

The double planetary mixer is a high-efficiency mixing equipment widely used in coatings, adhesives, pharmaceuticals and other industries. Its design concept is based on the rotation and revolution of the planetary mixer......

READ MORE -

The impact of motor failure on the industrial double planetary mixer is multifaceted and directly related to multiple key links such as production efficiency, product quality and equipment maintenance costs. As the core ......

READ MORE -

Temperature, humidity and pressure are key environmental factors that affect the mixing effect of materials. Their changes will not only significantly change the physical properties of the materials, but also directly af......

READ MORE

What are the technical advantages of industrial triple planetary mixer?

Triple planetary mixing system

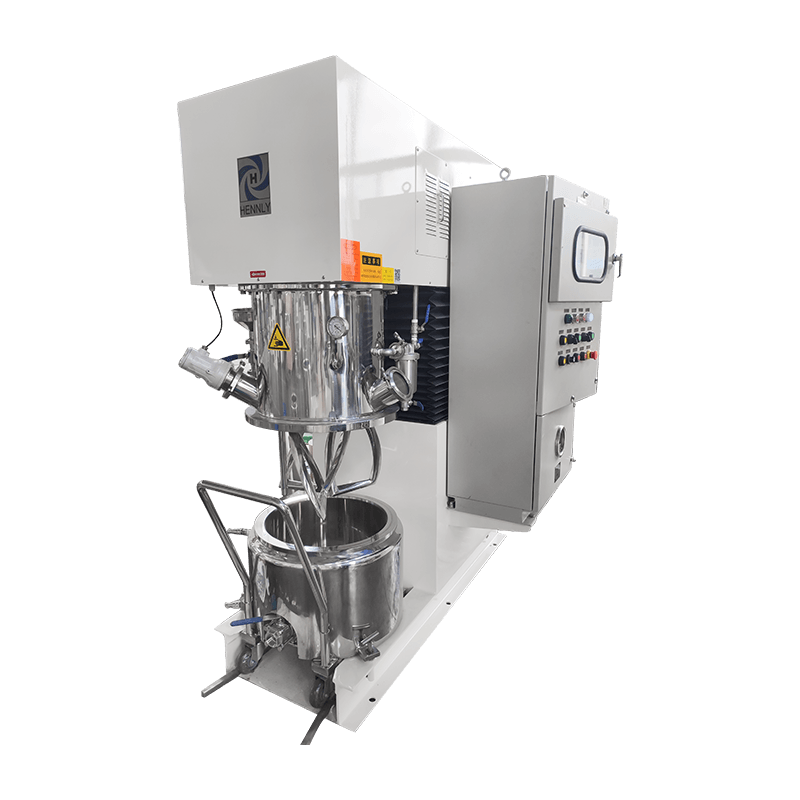

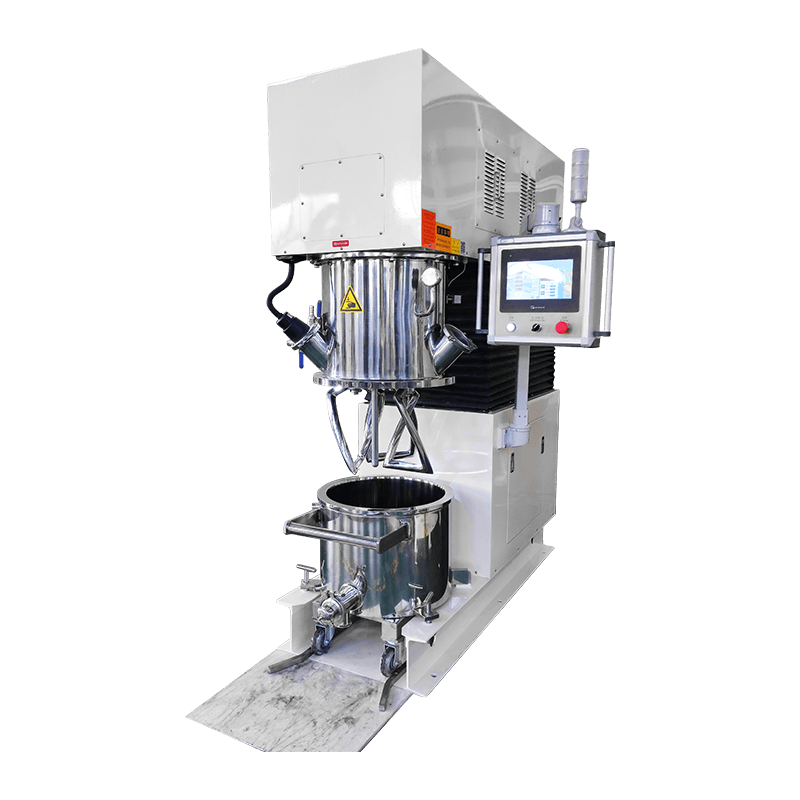

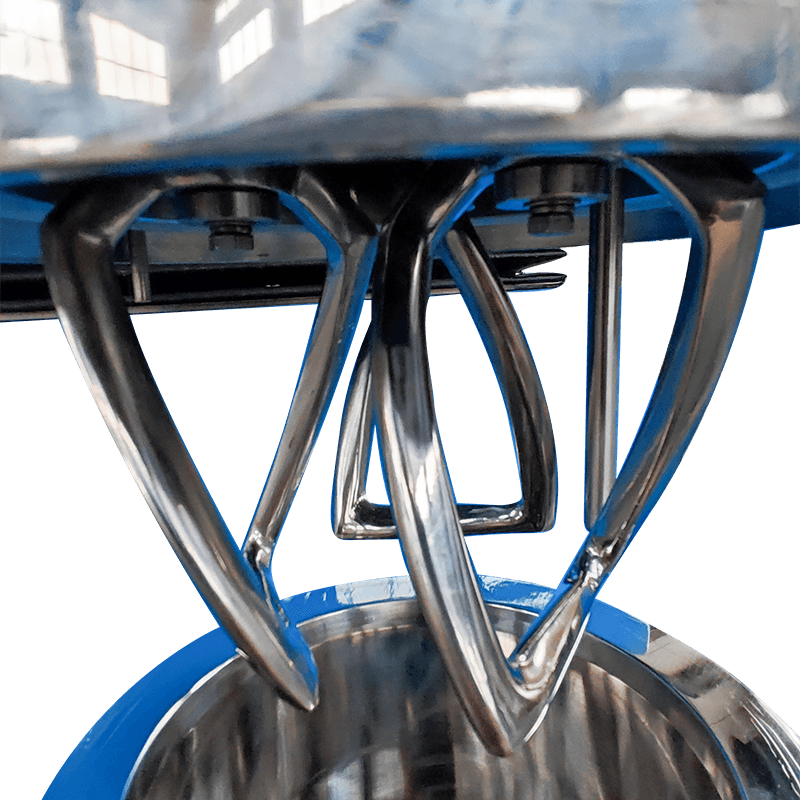

The core of Industrial Triple Planetary Mixer lies in its unique triple planetary mixing system. The system consists of a main shaft and multiple secondary shafts, forming a complex and efficient planetary motion trajectory. During the mixing process, the main shaft not only rotates, but the secondary shaft also revolves and rotates around the main shaft. This compound motion mode ensures that the mixing blades can cover every corner of the mixing barrel in all directions, achieving comprehensive mixing of materials and eliminating any dead corners. Compared with traditional mixers, the triple planetary mixing system significantly improves the mixing efficiency and ensures the uniform distribution of material components, which is undoubtedly a major technological breakthrough for industries that require high-precision mixing.

High-precision temperature control and wear-resistant materials

During the material mixing process, temperature control is crucial to maintaining the properties of the materials. NanTong Hennly fully recognizes this, so it is equipped with a high-precision temperature control system in the Industrial Triple Planetary Mixer. The system can monitor and adjust the temperature in the mixing barrel in real time to ensure that the materials are mixed in the best state and avoid quality degradation due to temperature fluctuations. At the same time, the mixing barrel and mixing blades are made of high-quality stainless steel or special alloy materials, which have extremely high wear resistance and corrosion resistance, and can meet the mixing needs of various corrosive or high-viscosity materials, further improving the overall quality of the product.

Wide range of applications and excellent mixing effects

With its excellent performance and wide range of applications, Industrial Triple Planetary Mixer has shown outstanding performance in many industries such as pharmaceuticals, chemicals, and food. In the pharmaceutical industry, this equipment is widely used in the mixing of materials such as powders, ointments, and liquid medicines to ensure uniform distribution of drug ingredients and improve the quality of drugs. In the chemical industry, it is suitable for mixing high-viscosity materials such as resins, glues, coatings, and inks, which significantly improves production efficiency and reduces energy consumption. In the food industry, this equipment can be used to mix raw materials such as flour, sugar, and milk powder to ensure the balance of food taste and nutrition. In addition, in cutting-edge fields such as new energy and new materials, Industrial Triple Planetary Mixer also plays an important role in the research and development and production of new products.

What are the precautions when using industrial triple planetary mixer?

Inspection and preparation before starting the equipment

Before starting the Industrial Triple Planetary Mixer, be sure to conduct a comprehensive equipment inspection and cleaning. First, make sure that there are no foreign matter and impurities in all parts of the equipment, such as the body, agitator, transmission device and mixing tank. This process is crucial because any tiny impurities may have a negative impact on the mixing effect or even cause damage to the equipment.

The inspection of electrical components should also not be ignored. The motor, circuit and other electrical components need to be carefully checked to ensure that they are operating normally and without faults. At the same time, ensure that the power connection is good and the grounding measures are in place. Electrical safety is the basis for the stable operation of the equipment. Any electrical failure may cause the equipment to stop or cause harm to the operator.

In addition, lubrication and maintenance are the key to ensure the normal operation of the equipment. Before use, the key parts of the equipment, such as the transmission device and bearings, should be properly lubricated to ensure smooth operation. Regular inspection of the motor and transmission device and timely replacement of wearing parts can effectively extend the service life of the equipment.

Precautions during operation

When using the Industrial Triple Planetary Mixer, the process requirements and operating procedures must be strictly followed. Random operation may cause damage to the equipment or substandard mixing effect. Therefore, operators should maintain a high degree of professionalism to ensure that each step of the operation meets the relevant standards.

It is crucial to control the opening and closing time of the equipment. The number of positive and reverse rotations of the equipment should be reasonably adjusted according to the process requirements to maintain the stable operation of the equipment and avoid failures caused by excessive wear. At the same time, when adding raw materials to the mixing tank, be sure to cut off the power first and adjust the speed of the agitator to the lowest. This measure is intended to prevent accidents when adding raw materials and ensure the safety of operators.

During the mixing process, it is strictly forbidden to disassemble the equipment or put your hands into the agitator at will. The high-speed rotating agitator may cause serious harm to the human body. Operators should always be vigilant to ensure their own safety. In addition, monitor the operating status of the equipment in real time. If any abnormality is found, the equipment should be stopped immediately for processing and the fault should be checked in time to prevent equipment damage or accidents.

Shutdown and maintenance

Before shutting down, the speed of the agitator should be adjusted to the lowest gear, and then the power should be cut off. This can effectively protect the equipment and avoid the impact caused by sudden shutdown.

After shutting down, the equipment should be cleaned immediately. Use a towel or brush to clean the raw material residue on the body shell to keep the equipment clean. This not only helps prevent corrosion and pollution, but also effectively extends the service life of the equipment.

Regular maintenance is a necessary measure to ensure the long-term and stable operation of the equipment. After daily use, maintenance work such as lubrication, cleaning and inspection is required. At the same time, regular detailed inspections of key parts such as motors, transmissions, bearings, etc. are carried out, and wearing parts are replaced in time to ensure that the equipment is always in the best working condition.

Are you interested in our products?

Experienced employees & experts are Always At Your Service to provide you with satisfactory products & professional instruction on technical problem solutions.