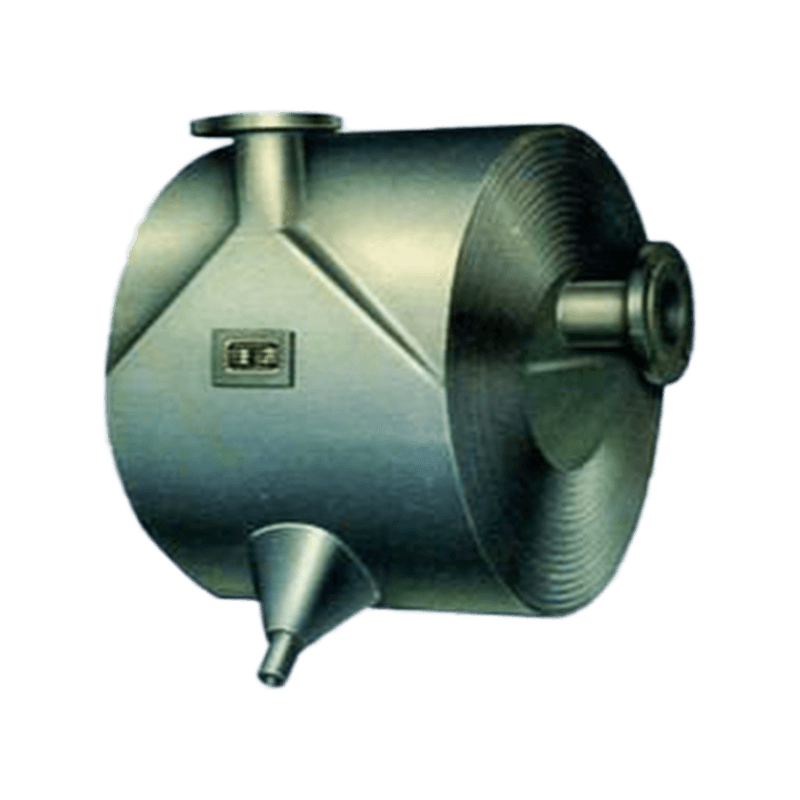

Heat Exchanger

About HENNLY

NanTong Hennly Machinery Equipment Co., Ltd. is China Heat Exchanger Suppliers and Wholesale Heat Exchanger Manufacturers that combines industry and trade, focusing on the research, development, and production of hybrid equipment. We have advanced processing equipment and a team that has served the mixer equipment industry for many years. Our employees have expertise, extensive application experience, and the ability to provide customers with a full range of process services from equipment selection to production. Based on high-quality and high-end markets, we mainly export to countries such as the United States, Germany, Japan, South Korea, Malaysia, Singapore, Vietnam, Indonesia, and Egypt. The areas of cooperation with clients include pharmaceuticals, adhesives, thermal conductivity and heat dissipation, slurry, solder paste, batteries, polymer materials, food, and chemical industries.

- Wide range of applications

- 15 years of precipitation of technical design

- Non-standard customization (it can be customized according to customer needs)

- Direct docking service of factory

-

The double planetary mixer is a high-efficiency mixing equipment widely used in coatings, adhesives, pharmaceuticals and other industries. Its design concept is based on the rotation and revolution of the planetary mixer......

READ MORE -

The impact of motor failure on the industrial double planetary mixer is multifaceted and directly related to multiple key links such as production efficiency, product quality and equipment maintenance costs. As the core ......

READ MORE -

Temperature, humidity and pressure are key environmental factors that affect the mixing effect of materials. Their changes will not only significantly change the physical properties of the materials, but also directly af......

READ MORE

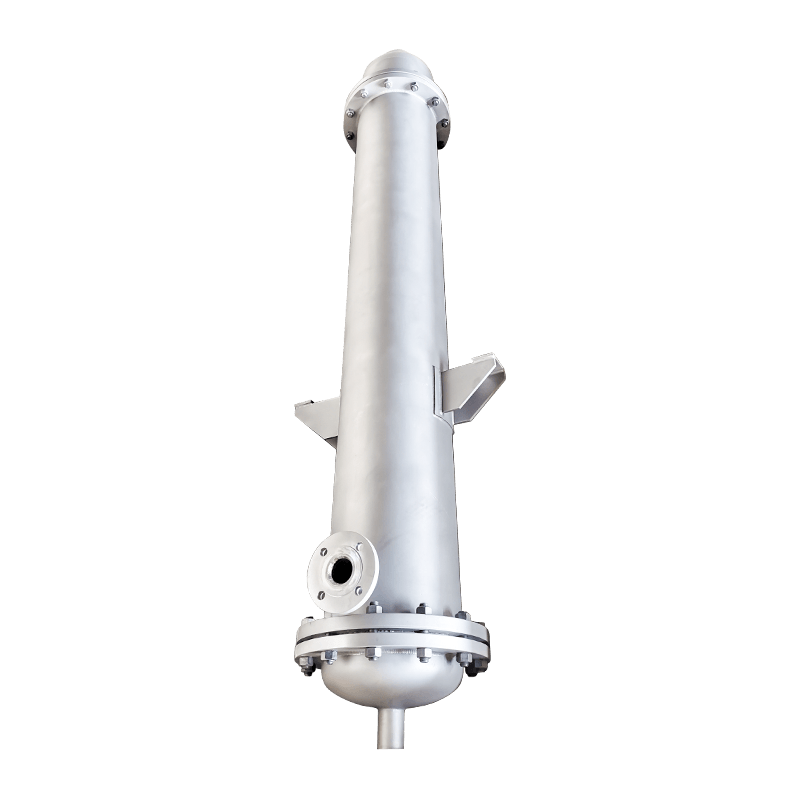

What is the function of industrial heat exchanger?

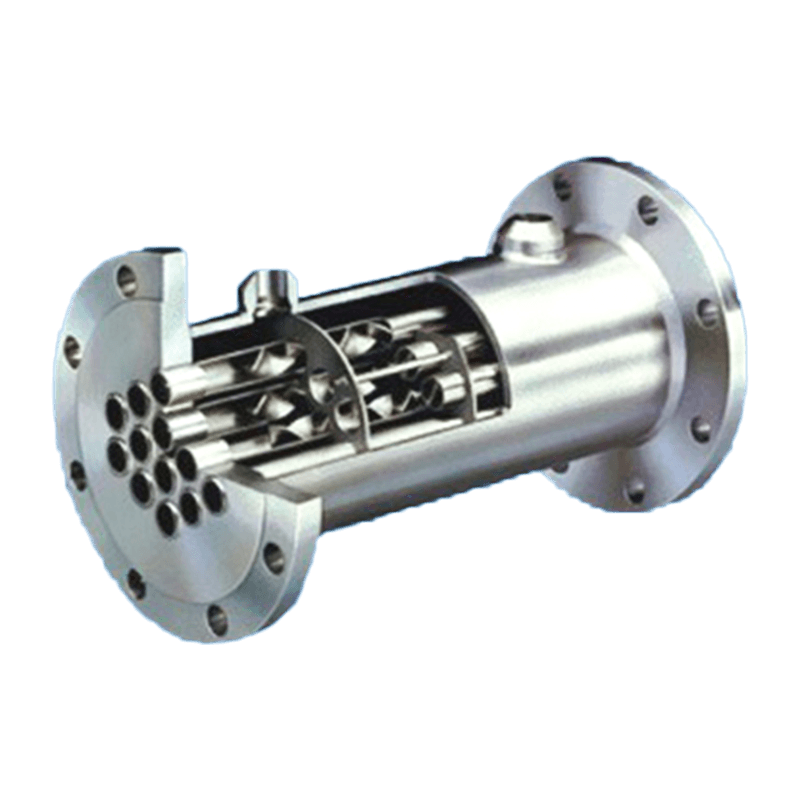

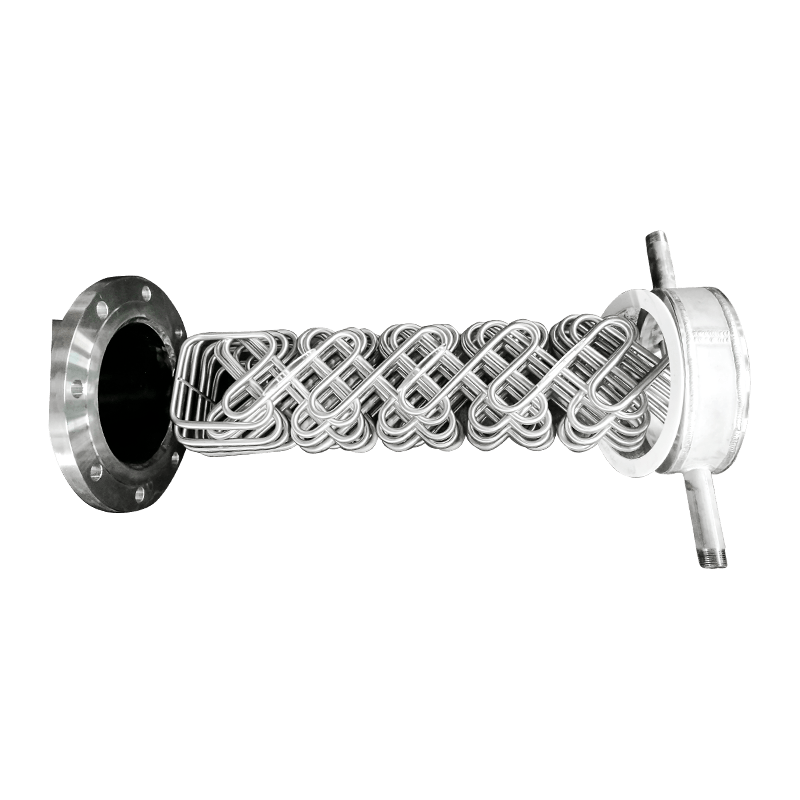

Industrial heat exchangers are key equipment for efficient heat transfer between different media. They are designed to ensure that the heat transfer process does not cause the mixing of media. This feature is particularly important in industrial applications that require precise temperature control. Whether used for heating, cooling, condensation or evaporation, industrial heat exchangers can effectively maintain the stable operation of process media within the set temperature range, thereby significantly improving production efficiency and product quality.

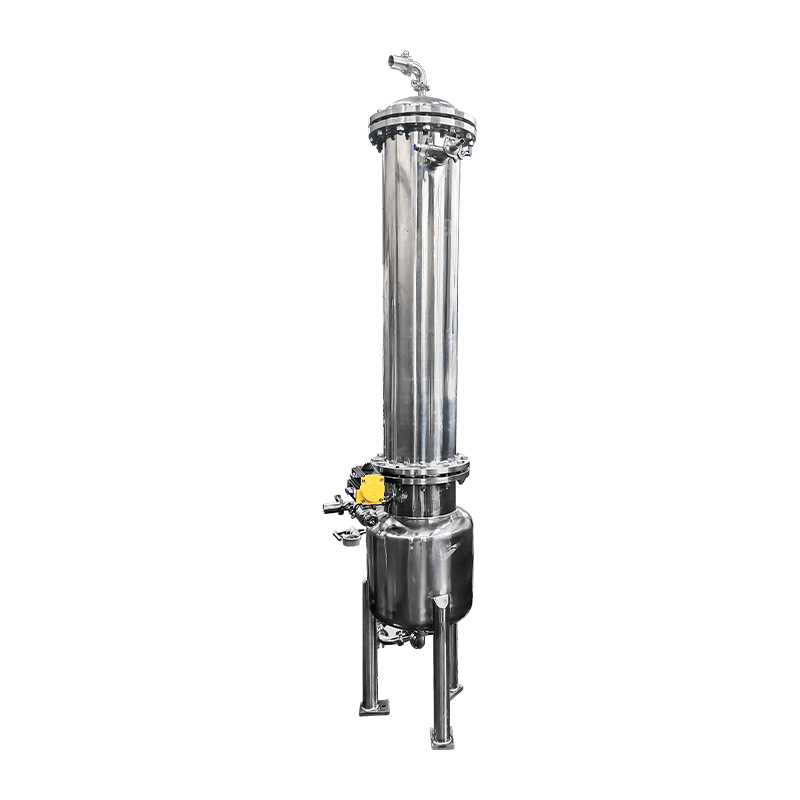

NanTong Hennly Machinery Equipment Co., Ltd. is committed to providing customers with efficient, durable and easy-to-maintain industrial heat exchangers. The company uses advanced heat transfer technology and high-quality materials such as stainless steel and titanium alloys to cope with corrosion and wear problems under various working conditions. By optimizing the structural design and adopting a variety of heat exchanger forms such as spiral plate, plate fin and shell and tube, the heat exchange efficiency and heat recovery rate are further improved. This structural innovation not only improves the working performance of the equipment, but also extends its service life and reduces maintenance costs.

Application scenarios and cases of industrial heat exchangers

NanTong Hennly Machinery Equipment Co., Ltd.'s industrial heat exchangers are widely used in many industries such as chemical, pharmaceutical, food processing and energy conversion. In the chemical industry, industrial heat exchangers play a vital role in the heating of crude oil and cooling of reaction products. Through precise temperature control, the smooth progress of chemical reactions and the generation of high-quality products are ensured. In the pharmaceutical industry, industrial heat exchangers are used for aseptic heat exchange and temperature control of drug production lines, which effectively improves the safety and stability of drugs and ensures the compliance of drug production processes.

In the food processing industry, the customized industrial heat exchanger solutions provided by NanTong Hennly Machinery Equipment Co., Ltd. can ensure that food maintains its nutritional content, flavor and safety during processing. Especially in the production of dairy products, juices and beer, these special heat exchangers effectively avoid product contamination and heat loss, and significantly improve production efficiency and product quality. For example, in dairy production, heat exchangers can reduce the growth of microorganisms while ensuring product temperature, thereby ensuring product safety.

What are the advantages of industrial heat exchanger in practical applications?

As an indispensable equipment in the modern industrial field, industrial heat exchangers are widely used in chemical, pharmaceutical, food processing and other industries with their excellent heat transfer capabilities and energy-saving and environmental protection characteristics.

Efficient heat transfer, improve production efficiency

The core competitiveness of industrial heat exchangers lies in their efficient heat transfer capabilities. NanTong Hennly Machinery Equipment Co., Ltd.'s products use industry-leading heat transfer technology and select high-performance materials such as stainless steel and titanium alloy. These materials have excellent corrosion resistance and high temperature resistance and can work stably in extreme environments. At the same time, through innovative structural designs, such as spiral plate, plate-fin and shell-and-tube types, the heat transfer area is significantly increased, the heat transfer path is shortened, and the heat transfer is achieved quickly and evenly.

Energy saving and environmental protection, help green production

Globally, green production and sustainable development have gradually become important directions for industrial development. NanTong Hennly Machinery Equipment Co., Ltd.'s industrial heat exchangers show significant energy-saving and environmental protection advantages in this context. Through precise temperature control, heat exchangers can maximize the use of energy, especially in the chemical industry, which can effectively recover the waste heat in the reaction process and convert it into reusable heat energy, significantly reducing energy waste. In the pharmaceutical and food processing industries, heat exchangers avoid excessive energy consumption and heat loss of products by precisely controlling the heating and cooling processes. In addition, the company also pays attention to environmental protection during the research and development process, and is committed to using fluorine-free refrigerants and biodegradable materials to reduce the impact on the environment.

Easy maintenance and reduced operation and maintenance costs

Easy maintenance is another significant advantage of industrial heat exchangers in practical applications. NanTong Hennly Machinery Equipment Co., Ltd.'s heat exchangers are reasonably designed and compact in structure, making them easy to disassemble and clean. This design not only greatly reduces the operation and maintenance costs of the equipment, but also improves the efficiency of the equipment. At the same time, the company provides comprehensive after-sales service and technical support to ensure that customers can solve problems encountered in a timely manner during use. In addition, NanTong Hennly Machinery Equipment Co., Ltd. has also actively introduced intelligent technology, and further improved the operation and maintenance efficiency and safety of the equipment through remote monitoring and fault warning.

Are you interested in our products?

Experienced employees & experts are Always At Your Service to provide you with satisfactory products & professional instruction on technical problem solutions.