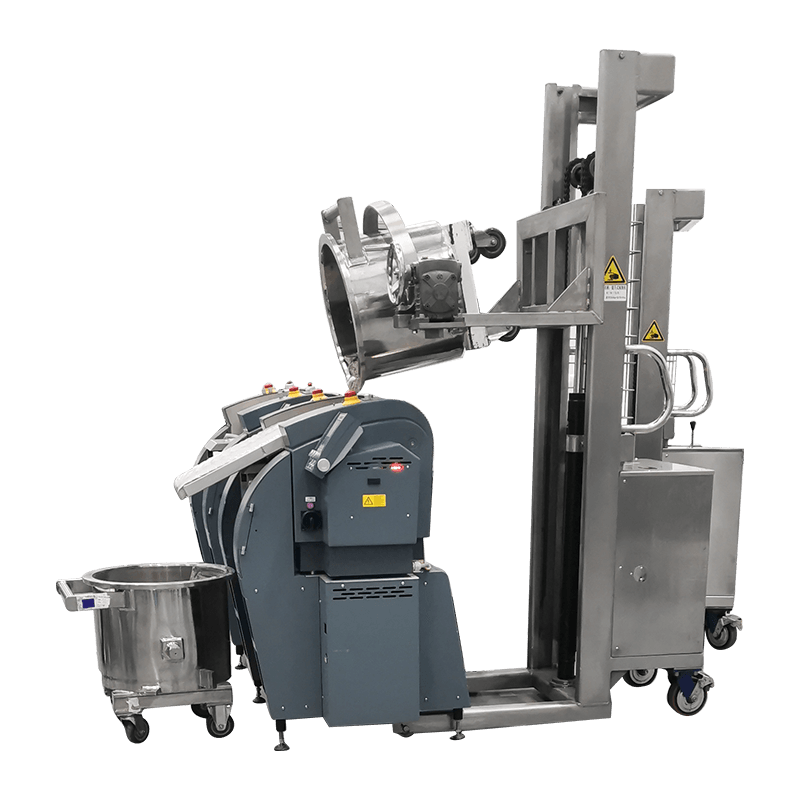

Discharging Cart

About HENNLY

NanTong Hennly Machinery Equipment Co., Ltd. is China Discharging Cart Suppliers and Wholesale Discharging Cart Manufacturers that combines industry and trade, focusing on the research, development, and production of hybrid equipment. We have advanced processing equipment and a team that has served the mixer equipment industry for many years. Our employees have expertise, extensive application experience, and the ability to provide customers with a full range of process services from equipment selection to production. Based on high-quality and high-end markets, we mainly export to countries such as the United States, Germany, Japan, South Korea, Malaysia, Singapore, Vietnam, Indonesia, and Egypt. The areas of cooperation with clients include pharmaceuticals, adhesives, thermal conductivity and heat dissipation, slurry, solder paste, batteries, polymer materials, food, and chemical industries.

- Wide range of applications

- 15 years of precipitation of technical design

- Non-standard customization (it can be customized according to customer needs)

- Direct docking service of factory

-

The double planetary mixer is a high-efficiency mixing equipment widely used in coatings, adhesives, pharmaceuticals and other industries. Its design concept is based on the rotation and revolution of the planetary mixer......

READ MORE -

The impact of motor failure on the industrial double planetary mixer is multifaceted and directly related to multiple key links such as production efficiency, product quality and equipment maintenance costs. As the core ......

READ MORE -

Temperature, humidity and pressure are key environmental factors that affect the mixing effect of materials. Their changes will not only significantly change the physical properties of the materials, but also directly af......

READ MORE

What are the structural design advantages of discharging cart?

Modular design

NanTong Hennly's discharging cart adopts an advanced modular design concept. This design not only improves the versatility of the equipment, but also significantly enhances its scalability. The modular structure enables each component to be replaced or upgraded independently, and customers do not need to make large-scale modifications to the entire equipment, thereby reducing maintenance costs. This flexible design concept enables the equipment to quickly adapt to new needs and technological changes that may arise in the future, ensuring the long-term value of the investment.

In our discharging cart, key components such as battery slots, discharging modules and safety protection devices are all modularly designed. Customers can flexibly choose modules of different specifications and quantities for combination according to specific production or testing requirements. This high degree of customization enables our discharging cart to demonstrate excellent performance in multiple fields such as battery manufacturing, energy storage system maintenance and laboratory testing, meeting diverse market needs.

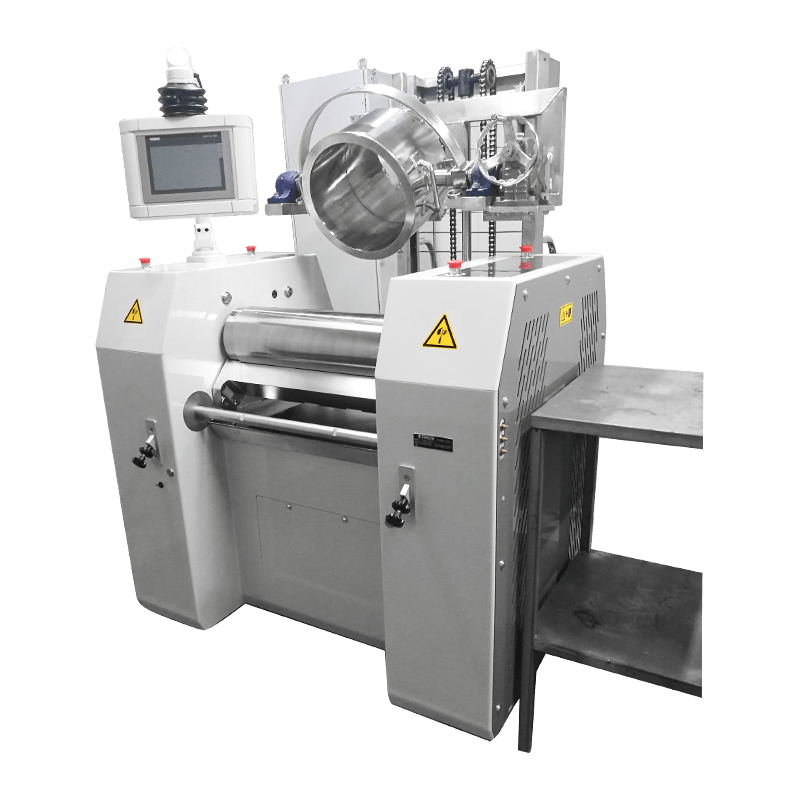

Intelligent control system

Intelligence is one of the important features of modern industrial equipment. NanTong Hennly's discharging cart is equipped with an advanced intelligent control system that can monitor the discharge status of the battery pack in real time, including multiple key parameters such as current, voltage, and temperature. Through precise control of the discharge process, the system ensures that the battery is discharged within a safe range, effectively avoiding potential risks such as overcharging and over-discharging, and ensuring the safety and reliability of the equipment.

In addition, the intelligent control system also has remote monitoring and data analysis functions. Users can view the discharge progress, battery status and historical data anytime and anywhere through mobile phone APP or computer software. These data not only help users to find and deal with problems in a timely manner, but also provide valuable reference for subsequent battery management and maintenance. Through data analysis, users can optimize discharge strategies and improve overall work efficiency.

Safety protection mechanism

Safety is one of the core elements of industrial equipment design. NanTong Hennly is well aware of this, so in the design of the discharge trolley, multiple safety protection mechanisms are adopted to ensure the safety of personnel and equipment.

In terms of electrical safety, we have equipped the discharge trolley with multiple electrical safety protection measures such as overload protection, short circuit protection, and over-temperature protection. These measures can respond quickly when abnormal conditions occur, cut off the power supply or adjust the discharge parameters, thereby effectively preventing equipment damage or casualties. In addition, the system also has a fault self-diagnosis function, which can promptly notify users of potential safety hazards.

In terms of mechanical safety, we use high-strength materials to manufacture the body and key components to ensure the stability and durability of the equipment. At the same time, the reasonable anti-collision structure and emergency braking system design can effectively deal with possible collisions or emergencies, further enhancing the safety of the product.

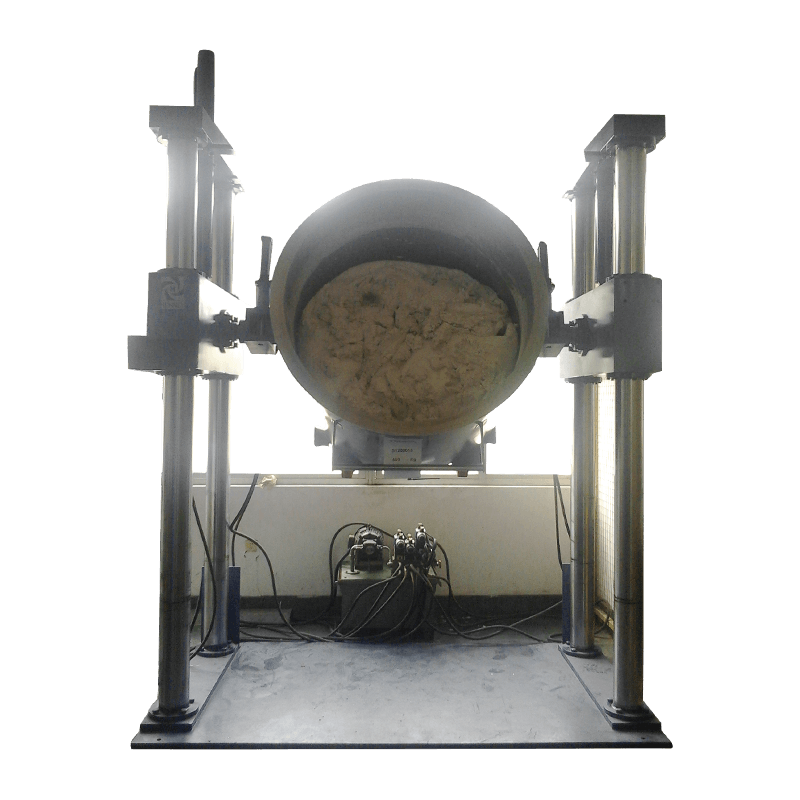

What are the safety performance protection measures of discharging carts?

Electrical safety protection

Electrical safety is one of the core elements of the design of discharging carts. NanTong Hennly fully recognizes the importance of electrical safety, so multiple electrical safety protection mechanisms are incorporated into the discharging cart to ensure the safety of equipment and operators.

In terms of overload protection, we use advanced technology to monitor the load in real time during the operation of the equipment. When the system detects an overload, the protection mechanism will quickly intervene to automatically cut off the power supply or adjust the working parameters, thereby effectively preventing equipment damage and potential fire risks. In addition, in order to deal with possible short circuits, we have designed an efficient short-circuit protection circuit. Once the system identifies a short circuit, the discharging operation will stop immediately and an alarm signal will be issued to remind the operator to take timely measures.

In order to ensure that the equipment will not be damaged due to overheating during long-term operation, we have equipped the discharging cart with an overtemperature protection mechanism. The mechanism monitors the temperature of the equipment in real time. Once the set threshold is exceeded, the system will automatically stop working to prevent the temperature from continuing to rise and causing safety accidents. At the same time, grounding protection measures are also crucial. We ensure that the equipment is reliably connected to the ground to prevent static electricity or leakage during the discharge process, thereby protecting the safety of personnel and equipment in all aspects.

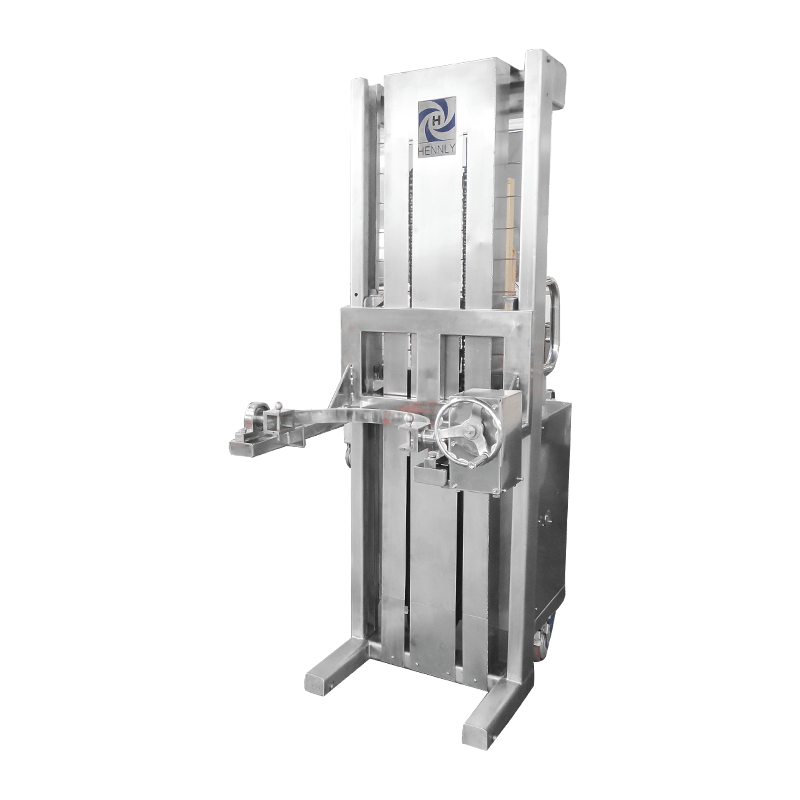

Mechanical safety protection

In terms of mechanical safety, NanTong Hennly also pays attention to details and quality. Our discharge trolley uses high-strength materials to manufacture the body and key components to ensure the stability and durability of the equipment.

We have designed a reasonable anti-collision structure for the discharge trolley to cope with possible collisions. This structure can not only effectively absorb the collision energy, but also protect the internal electronic components from damage. In addition, the design of the emergency brake system also provides protection for equipment safety. In an emergency, the operator only needs to press the emergency brake button, and the equipment will stop running immediately, effectively avoiding potential safety risks.

A stable support structure is another important aspect of our design. We fully consider the stability of the discharge trolley during work and adopt a stable support structure design to ensure that the equipment will not tip over or shift during work. This design not only improves the safety of the device, but also ensures that the battery pack is securely fixed during discharge, further enhancing the reliability of the overall product.

Are you interested in our products?

Experienced employees & experts are Always At Your Service to provide you with satisfactory products & professional instruction on technical problem solutions.