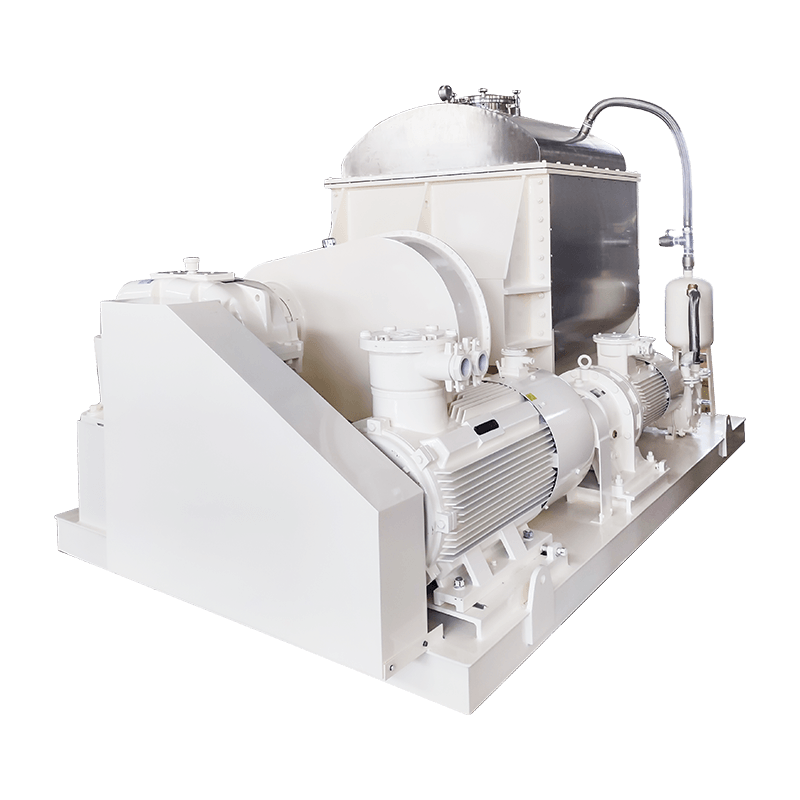

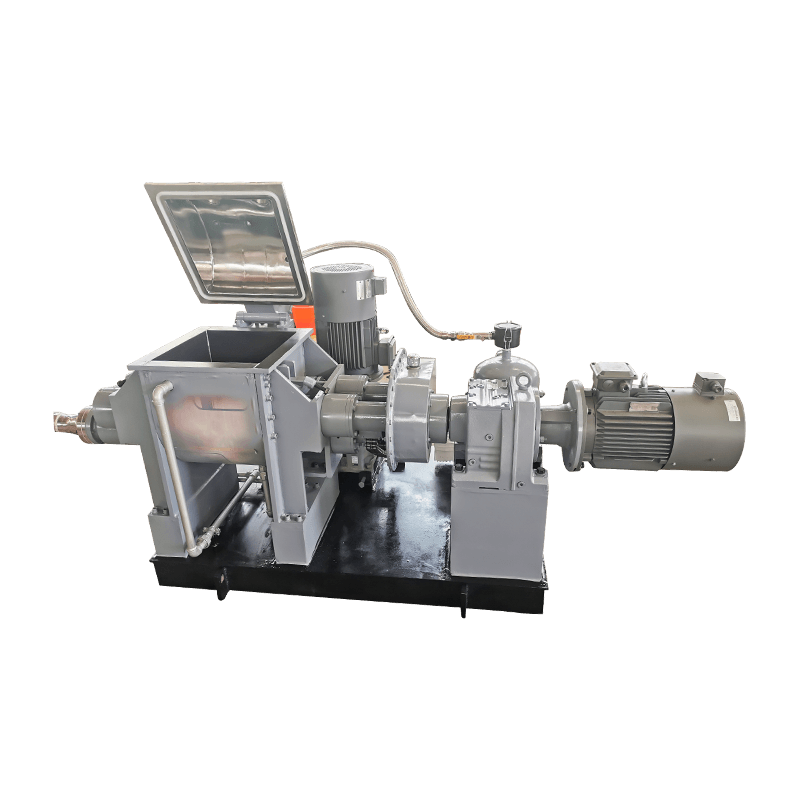

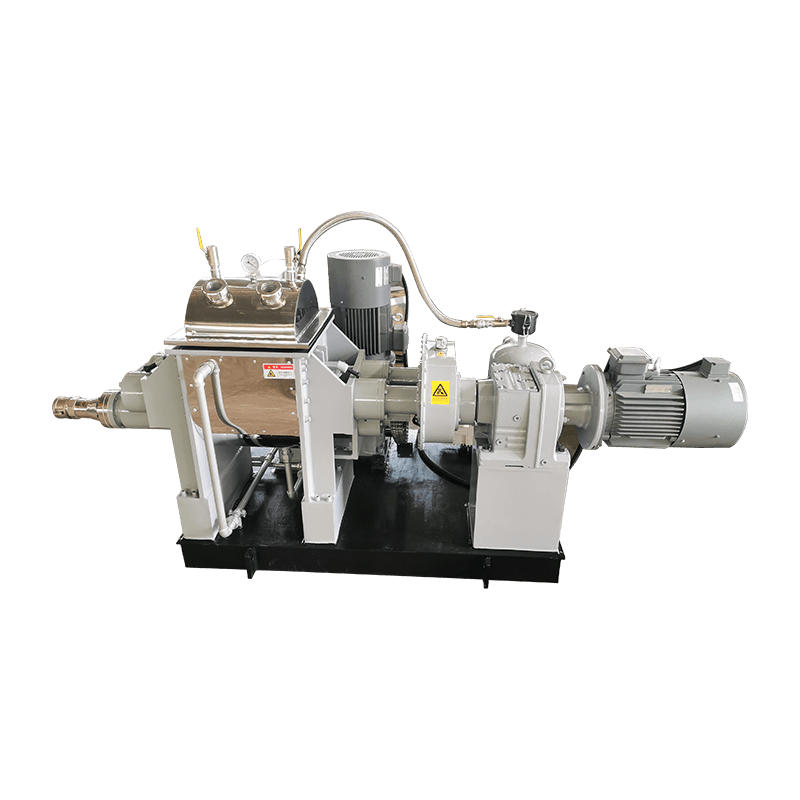

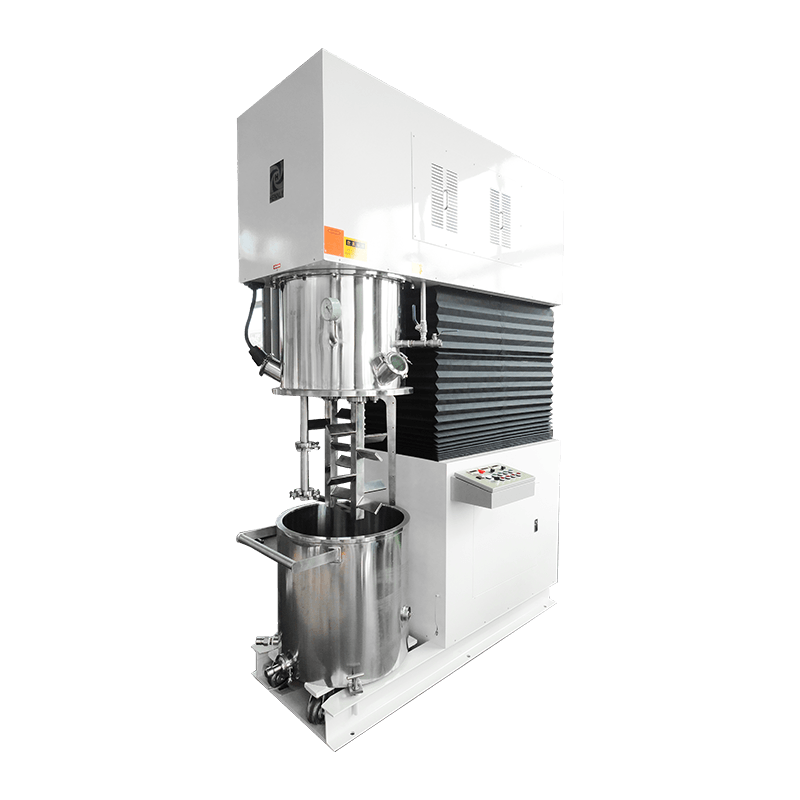

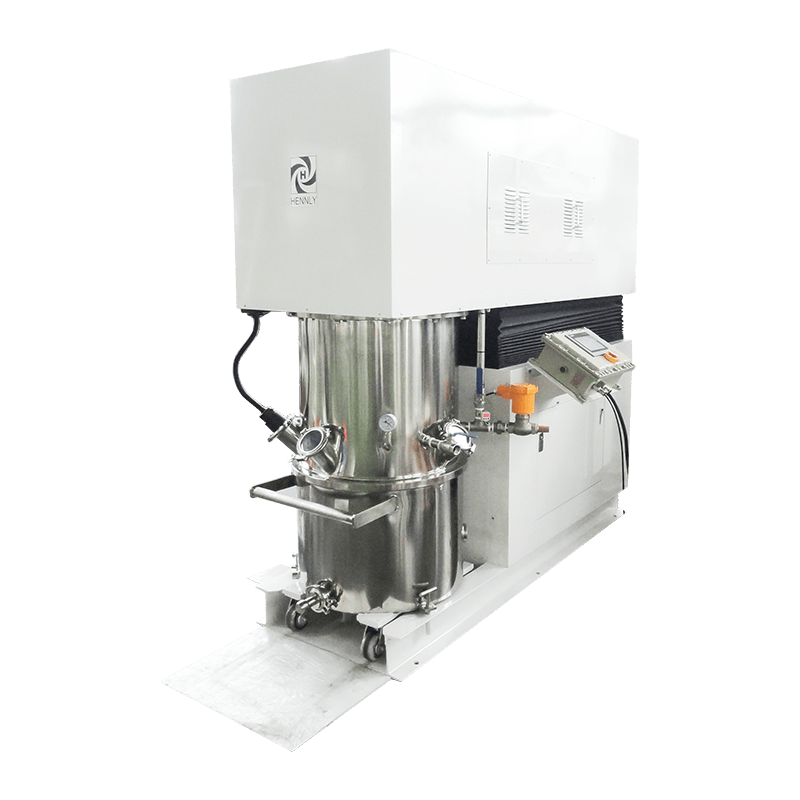

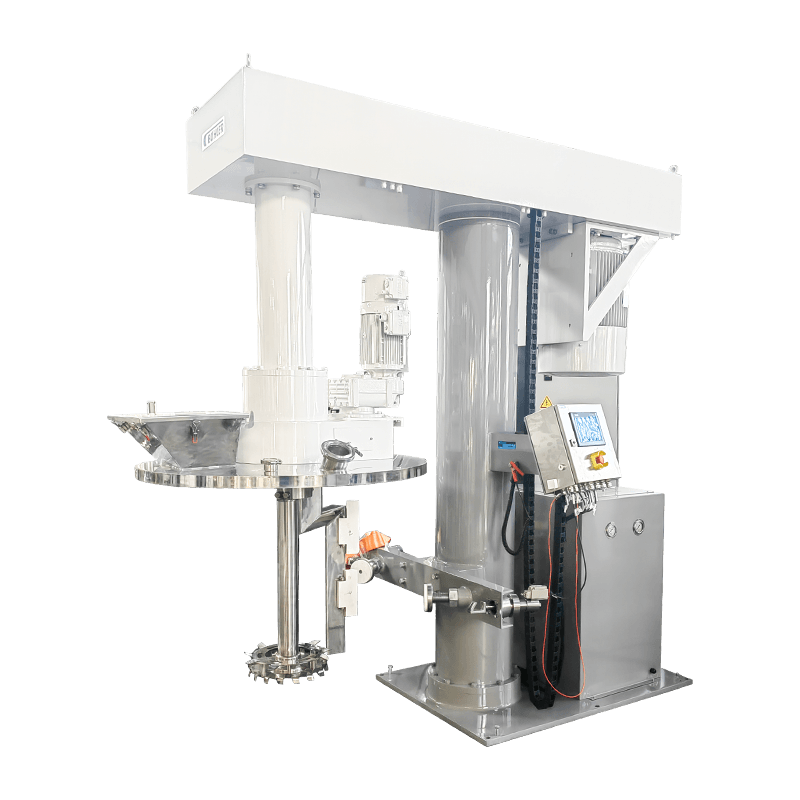

Kneading Machine

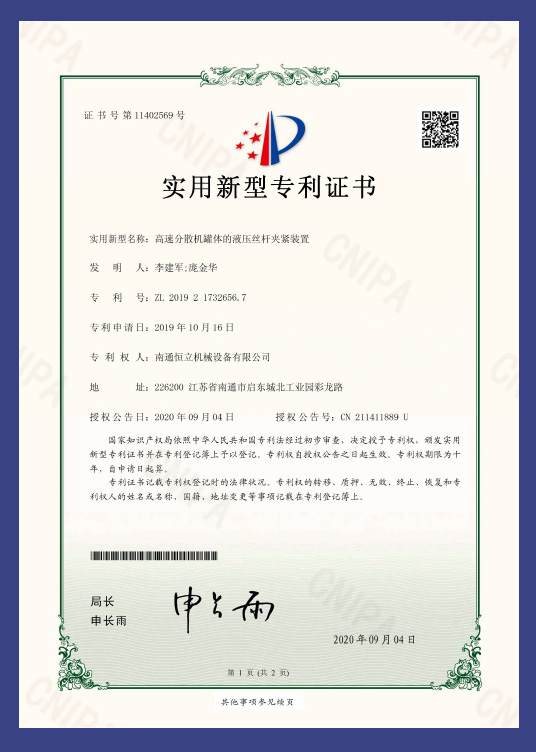

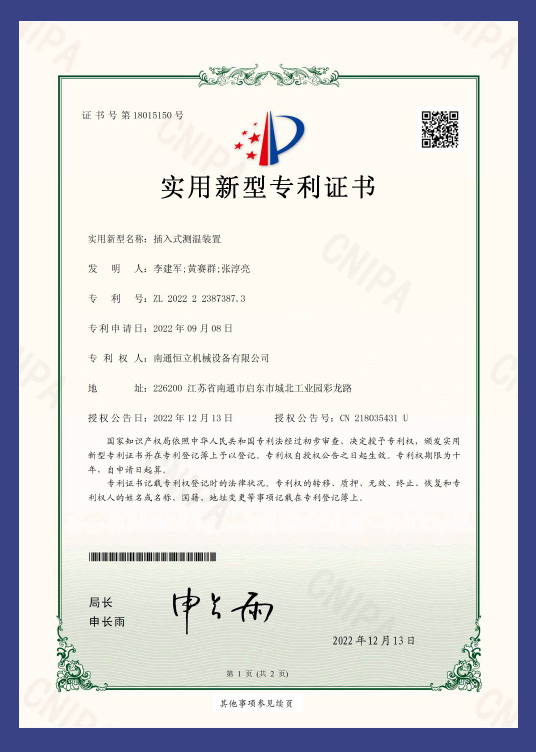

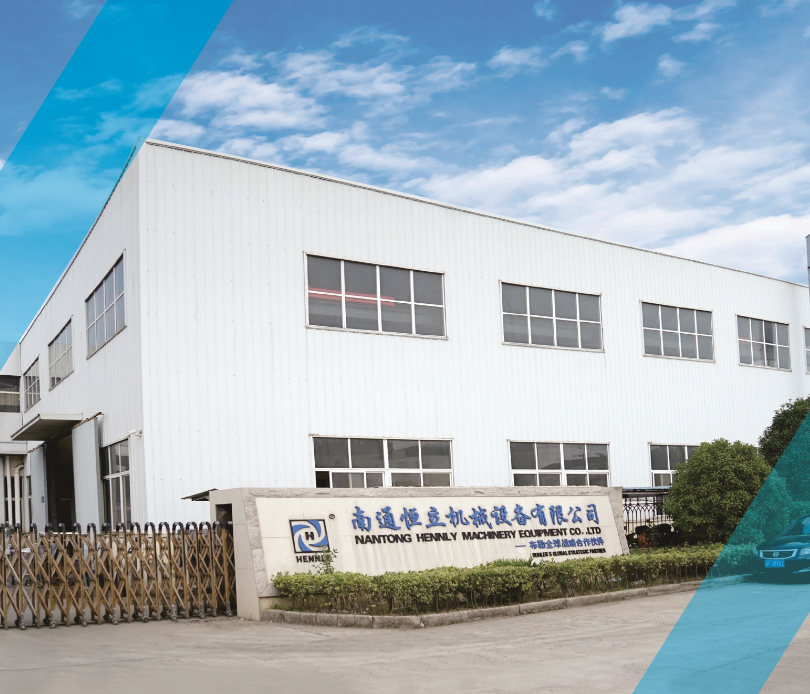

About HENNLY

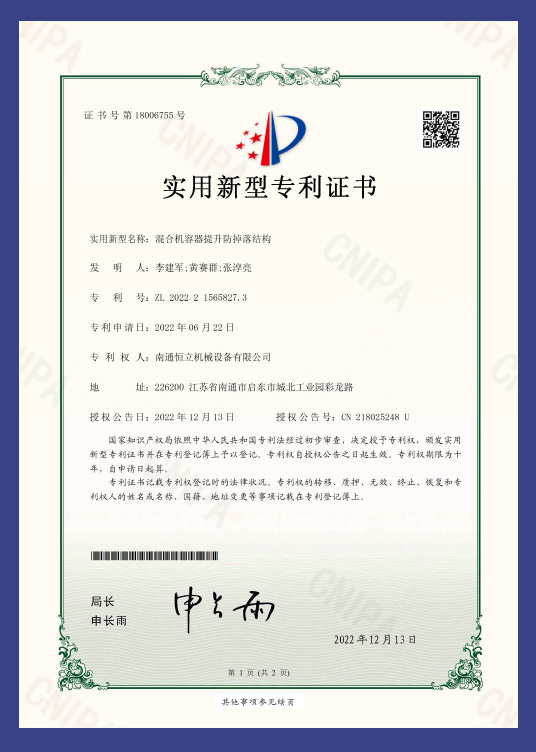

NanTong Hennly Machinery Equipment Co., Ltd. is China Kneading Machine Suppliers and Wholesale Kneading Machine Manufacturers that combines industry and trade, focusing on the research, development, and production of hybrid equipment. We have advanced processing equipment and a team that has served the mixer equipment industry for many years. Our employees have expertise, extensive application experience, and the ability to provide customers with a full range of process services from equipment selection to production. Based on high-quality and high-end markets, we mainly export to countries such as the United States, Germany, Japan, South Korea, Malaysia, Singapore, Vietnam, Indonesia, and Egypt. The areas of cooperation with clients include pharmaceuticals, adhesives, thermal conductivity and heat dissipation, slurry, solder paste, batteries, polymer materials, food, and chemical industries.

- Wide range of applications

- 15 years of precipitation of technical design

- Non-standard customization (it can be customized according to customer needs)

- Direct docking service of factory

What factors affect the performance of industrial kneading machine

Motor and transmission system

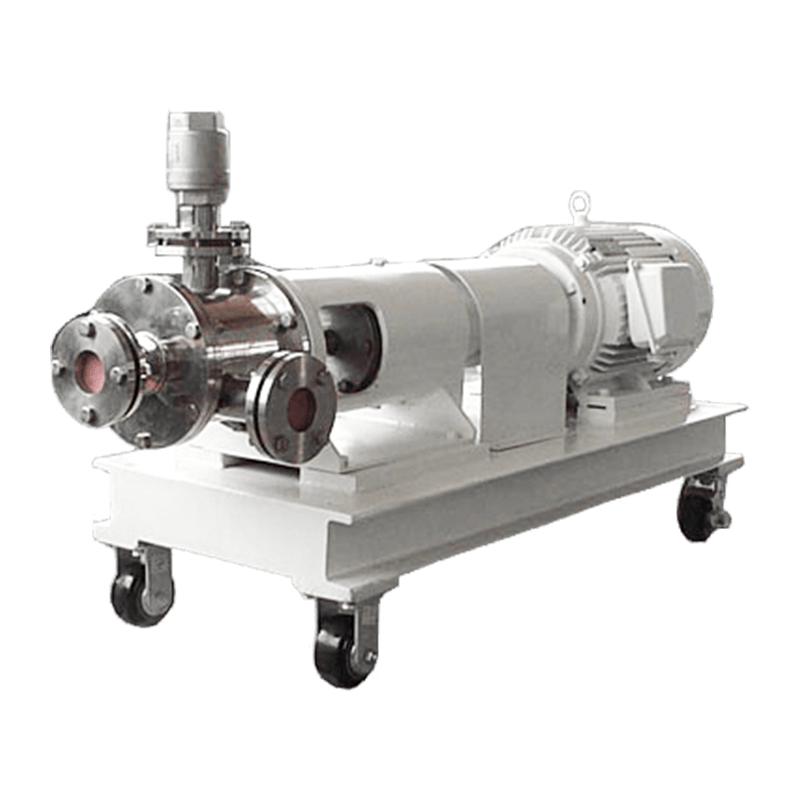

The motor and transmission system are the core components of industrial kneading machines, and their performance is directly related to the operating efficiency and stability of the equipment. NanTong Hennly uses advanced motors with high efficiency and low energy consumption to ensure that the equipment maintains excellent performance during long-term operation. Through the optimized gear transmission structure, energy loss can be significantly reduced and transmission efficiency can be improved, so that the equipment can achieve uniform mixing of raw materials during the kneading process, thereby improving the quality of the final product.

Mixing and kneading mechanism design

The design of the mixing and kneading mechanism is another important factor affecting the performance of industrial kneading machines. NanTong Hennly's industrial kneading machine adopts a unique mixing and kneading mechanism, which achieves uniform mixing and deep kneading of raw materials through precise mechanical structure and optimized workflow. This design not only significantly improves the production efficiency of the equipment, but also ensures that the final product has a fine texture and a more outstanding taste.

Material and manufacturing process

The material and manufacturing process of the equipment are one of the key factors affecting the performance of industrial kneading machines. NanTong Hennly is well aware of this, so it uses high-quality stainless steel and high-strength alloy materials in the manufacturing process. These materials not only have excellent corrosion resistance and wear resistance, but also maintain stable performance even in long-term and high-intensity use environments. In addition, NanTong Hennly pays attention to the refinement of manufacturing processes, and through strict quality control and advanced manufacturing technology, ensures that each industrial kneading machine has excellent performance and long-lasting service life.

Maintenance and care

The maintenance and care of equipment is an important link that affects the performance of industrial kneading machines. NanTong Hennly is well aware of this, so it provides users with detailed maintenance and care guidelines and dispatches professional technicians for regular inspections and maintenance. Through timely maintenance and care, the equipment can always be kept in the best operating condition, extend its service life, and reduce the operating costs of the enterprise. NanTong Hennly is committed to providing customers with high-quality after-sales service to ensure the performance of the equipment during its life cycle.

What are the operating specifications for the use of industrial kneading machine

Preparation before starting

Environmental inspection

Before starting the industrial kneading machine, a comprehensive assessment of its working environment must be conducted. Ensure that the area around the equipment is clean and free of debris and maintain good ventilation conditions to prevent the equipment from malfunctioning due to excessive temperature. At the same time, check whether the voltage of the power supply is consistent with the rated voltage indicated on the equipment nameplate to avoid equipment damage or performance degradation due to unstable voltage.

Equipment inspection

It is essential to conduct a systematic inspection of the industrial kneading machine. Make sure that all parts are firmly installed, the transmission system operates flexibly, and the safety protection devices are intact. Pay special attention to the mixing blades to ensure that they are not deformed or cracked, and the inside of the mixing tank must be kept clean and free of foreign matter.

Material preparation

Prepare an appropriate amount of raw materials in advance according to the production plan. Ensure that the quality of the materials used meets the production standards, and it is strictly forbidden to use expired or deteriorated raw materials. At the same time, the working parameters of the equipment, such as kneading speed and time, should be appropriately adjusted according to the characteristics of different materials to ensure production efficiency and product quality.

Start-up operation

Start the equipment

After confirming that all preparations are correct, start the industrial kneading machine according to the provisions of the equipment operation manual. First turn on the power switch, and then gradually adjust to the required working speed. During the startup process, pay close attention to the operating status of the equipment. If any abnormality is found, stop the equipment immediately for inspection.

Feeding and mixing

After the equipment reaches a stable working state, start feeding. Feeding should be uniform and appropriate, and avoid feeding too much material at one time to avoid overloading the equipment. According to the characteristics of the material and the production process requirements, adjust the mixing speed and time in time to ensure that the materials are fully mixed.

Monitoring and adjustment

During the kneading process, it is necessary to continuously monitor the operation of the equipment and the state of the materials. If uneven mixing of materials, abnormal vibration of the equipment or increased noise are found, the equipment should be stopped immediately for inspection and adjustment of relevant parameters. In addition, it is necessary to regularly check the wear of the mixing blades and mixing cylinders, and replace the seriously worn parts in time to ensure the normal operation of the equipment.

Shutdown and cleaning

Normal shutdown

After completing the production task, the equipment should be shut down normally according to the requirements of the equipment operation manual. After gradually reducing the working speed, turn off the power switch. After shutting down, wait until the equipment stops running completely before proceeding with subsequent operations.

Cleaning and maintenance

After shutting down, the industrial kneading machine must be thoroughly cleaned. The mixing cylinder and mixing blades can be cleaned with clean water or special detergent to ensure that there is no residual material. At the same time, check whether the parts are loose or damaged, and tighten or replace them in time. In addition, the equipment should be lubricated and maintained regularly to extend its service life.

Safety operating specifications

Operator training

All operators must receive professional training before taking up their posts and be familiar with the structure, performance and operating procedures of the equipment. Ensure that the operator can operate the industrial kneading machine correctly and skillfully to avoid equipment damage or safety accidents caused by improper operation.

Safety protection measures

When operating the industrial kneading machine, the operator must wear appropriate personal protective equipment, such as work clothes, gloves and safety shoes. At the same time, ensure that the safety protection devices of the equipment are intact and effective, including emergency stop buttons and protective covers. During the operation of the equipment, it is strictly forbidden to touch the rotating parts or cross the mixing tank to ensure personal safety.

Are you interested in our products?

Experienced employees & experts are Always At Your Service to provide you with satisfactory products & professional instruction on technical problem solutions.