Static Mixer

About HENNLY

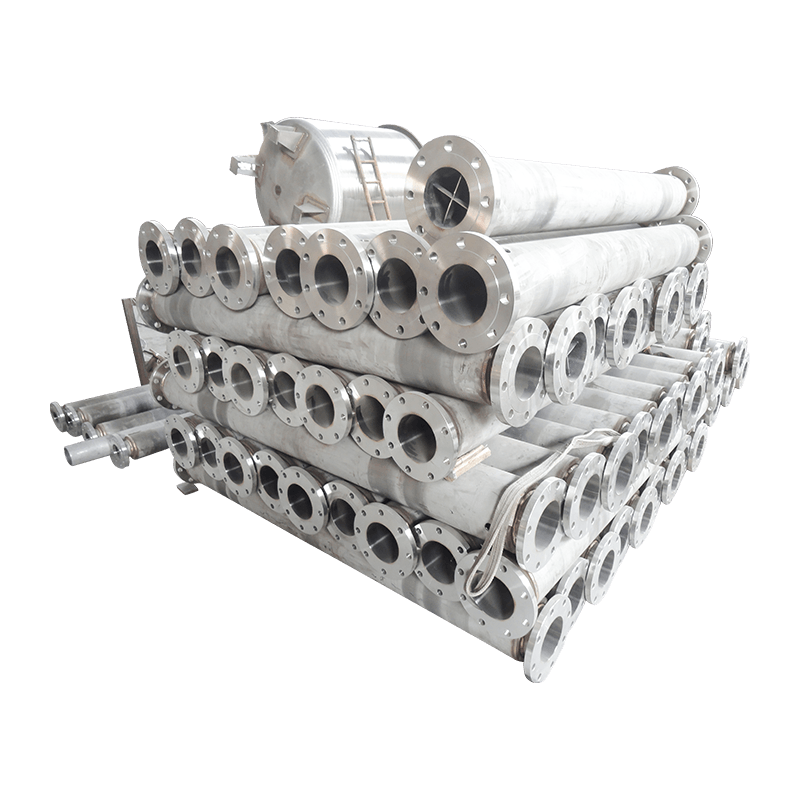

NanTong Hennly Machinery Equipment Co., Ltd. is China Static Mixer Suppliers and Wholesale Static Mixer Manufacturers that combines industry and trade, focusing on the research, development, and production of hybrid equipment. We have advanced processing equipment and a team that has served the mixer equipment industry for many years. Our employees have expertise, extensive application experience, and the ability to provide customers with a full range of process services from equipment selection to production. Based on high-quality and high-end markets, we mainly export to countries such as the United States, Germany, Japan, South Korea, Malaysia, Singapore, Vietnam, Indonesia, and Egypt. The areas of cooperation with clients include pharmaceuticals, adhesives, thermal conductivity and heat dissipation, slurry, solder paste, batteries, polymer materials, food, and chemical industries.

- Wide range of applications

- 15 years of precipitation of technical design

- Non-standard customization (it can be customized according to customer needs)

- Direct docking service of factory

-

The double planetary mixer is a high-efficiency mixing equipment widely used in coatings, adhesives, pharmaceuticals and other industries. Its design concept is based on the rotation and revolution of the planetary mixer......

READ MORE -

The impact of motor failure on the industrial double planetary mixer is multifaceted and directly related to multiple key links such as production efficiency, product quality and equipment maintenance costs. As the core ......

READ MORE -

Temperature, humidity and pressure are key environmental factors that affect the mixing effect of materials. Their changes will not only significantly change the physical properties of the materials, but also directly af......

READ MORE

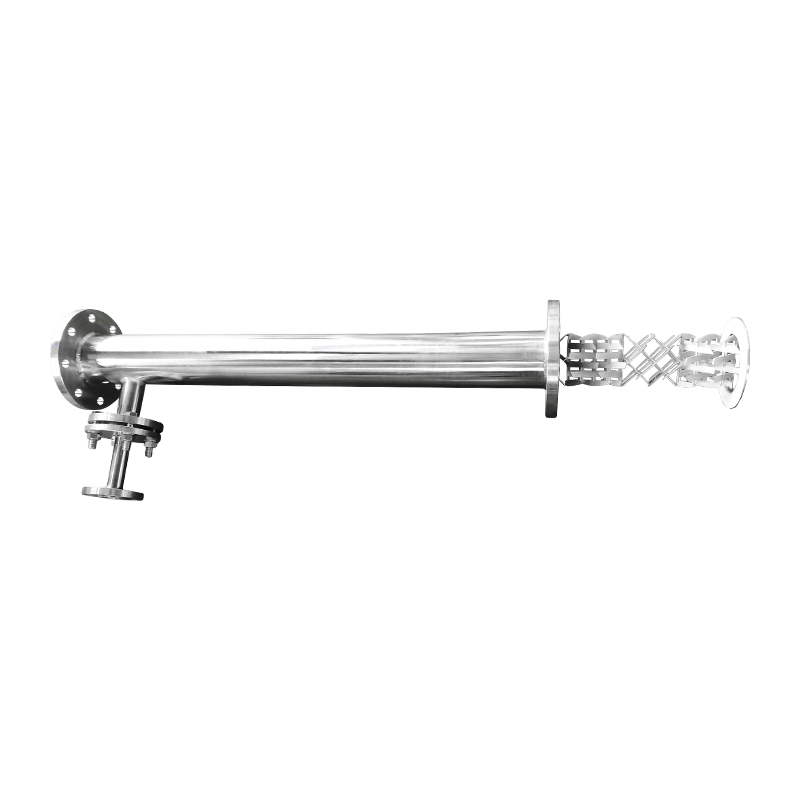

Working principle of industrial static mixer

Industrial static mixer is an efficient device that relies on the fluid's own energy to achieve fluid mixing through mixing elements fixed in the pipeline. Its working principle is based on the interaction between laminar flow and turbulence to form a complex flow pattern to achieve excellent mixing effect.

After the fluid enters the static mixer, it first contacts a series of carefully designed mixing elements. These elements change the flow direction, velocity and pressure distribution of the fluid, causing the fluid to undergo a process of "division-position movement-reunion" in a laminar state. The fluid is cut into multiple thin layers and continuously reorganized and interlaced in subsequent mixing elements to achieve preliminary mixing.

As the fluid continues to flow, the turbulent effect gradually emerges. In a turbulent state, the fluid not only undergoes a laminar mixing process, but also produces violent vortices in the cross-sectional direction. These vortices significantly enhance the collision and diffusion between fluid molecules, making the mixing effect more uniform and efficient.

NanTong Hennly fully considered the principles of fluid dynamics in the design of the static mixer. By optimizing the shape, size and arrangement of the mixing elements, the fluid flow pattern can be precisely controlled. This design not only improves mixing efficiency, but also effectively reduces energy consumption and maintenance costs.

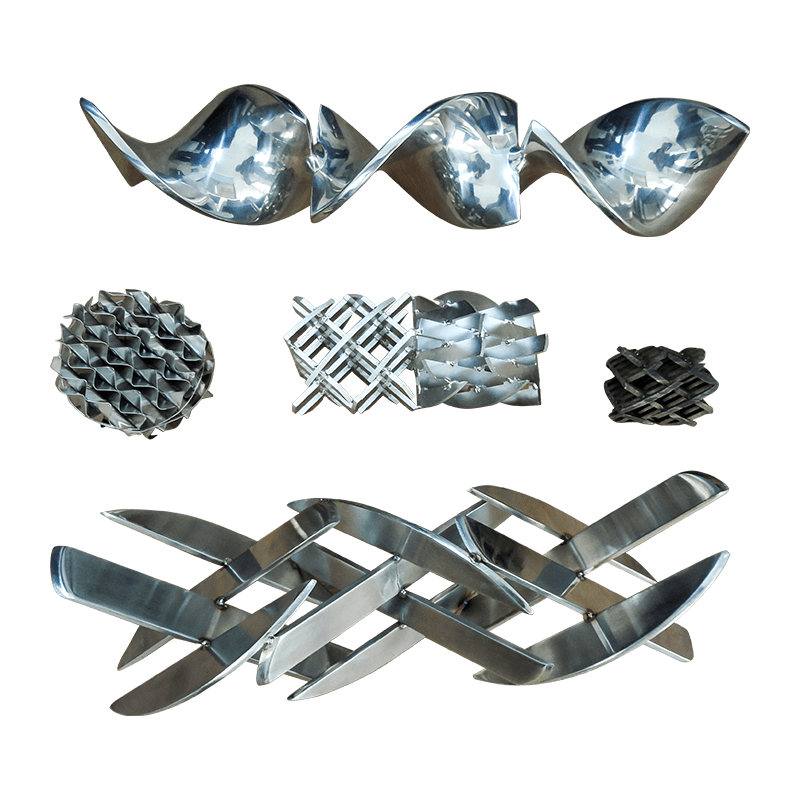

Technical highlights of NanTong Hennly industrial static mixers

High-efficiency mixing capacity: NanTong Hennly's industrial static mixers adopt an innovative mixing element design, which can achieve uniform mixing of fluids in a very short time, significantly improving production efficiency. Its design concept aims to maximize the mixing effect and ensure the consistency and quality of the final product.

Low energy consumption and environmental protection: The equipment does not require an external power source and relies entirely on the energy of the fluid itself to complete the mixing process, greatly reducing energy consumption. At the same time, its leak-free design meets the strict requirements of today's environmental protection and reduces the impact on the environment.

Wide applicability: NanTong Hennly's static mixers can cope with a variety of fluid characteristics, including high-viscosity fluids, corrosive fluids, and fluids containing solid particles. This makes it have a wide range of application potential in many industries such as chemical, pharmaceutical, and food processing.

Easy to maintain and clean: The equipment has a simple structure and no moving parts, which significantly reduces maintenance costs. Its design takes into account the characteristics of easy disassembly and cleaning, which not only extends the service life of the equipment, but also reduces downtime and improves production efficiency.

Application areas of industrial static mixer

The mainstay of the chemical industry

In the chemical industry, industrial static mixers are core equipment. Their efficient and stable mixing performance plays a vital role in the production processes of synthetic resins, coatings, paints and adhesives. NanTong Hennly's static mixers use advanced mixing element design, which can accurately control the mixing ratio and uniformity of the fluid to ensure that the quality of the final product remains consistent and stable between batches. In addition, NanTong Hennly provides customized mixing solutions for the characteristics of high-viscosity and corrosive fluids, which not only effectively extends the service life of the equipment, but also significantly reduces maintenance costs and improves overall production efficiency.

Quality assurance in the food industry

In the food industry, industrial static mixers are widely used in the mixing and homogenization of foods such as juice, milk and condiments. NanTong Hennly's static mixers are made of food-grade materials that meet international food safety standards to ensure that the entire mixing process is pollution-free and residue-free. Its excellent mixing performance ensures the uniform distribution of food ingredients, thereby improving the taste and nutritional value of the product. In juice production, static mixers can effectively remove bubbles and impurities from juice, significantly improve the clarity and transparency of the product, and provide consumers with a better beverage experience.

Innovation in the pharmaceutical industry

In the pharmaceutical industry, industrial static mixers are key equipment for the preparation and mixing of liquid medicines, vaccines and other biological agents. NanTong Hennly's static mixers use high-precision mixing elements to ensure the activity and stability of biological agents during the mixing process. In addition, its design is easy to clean and maintain, in line with the GMP (Good Manufacturing Practice) standards of the pharmaceutical industry, and effectively avoid the risk of cross-contamination. In the vaccine preparation process, static mixers can accurately control the dilution ratio and mixing uniformity of the vaccine, thereby ensuring the effectiveness and safety of the vaccine, and helping pharmaceutical companies improve production efficiency and product quality.

Are you interested in our products?

Experienced employees & experts are Always At Your Service to provide you with satisfactory products & professional instruction on technical problem solutions.